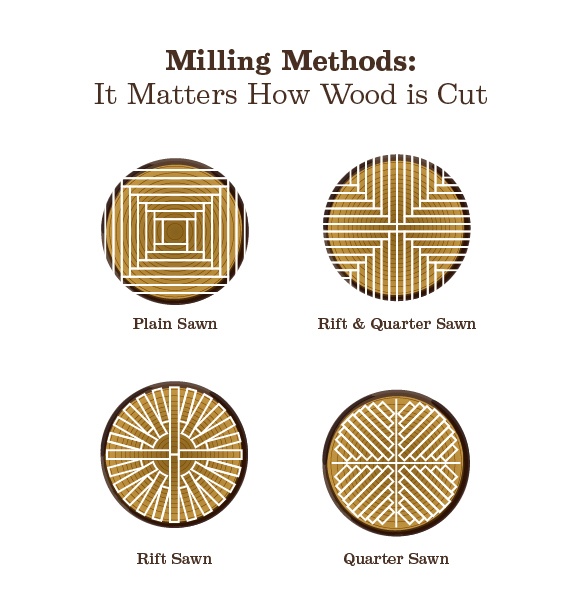

As trees are sawn into hardwood flooring planks, the way in which the wood is cut will greatly affect how the resulting floors will look, particularly the grain. The cut also influences the stability of the wood.

That’s why it’s important to pay attention to the milling method used when choosing the wood for your hardwood floors.

The four basic types of cuts used for flooring are:

The four basic types of cuts used for flooring are:

Plain sawn

Plain sawn (i.e., “flat sawn”) is the simplest and most common milling method—parallel cuts are made lengthwise along a log. This cut allows for the greatest grain variation, and in some cases, can even highlight the grain. Depending on the wood species, what’s referred to as the “cathedral affect” can occur—so named because the open grain forms a prominent wavy pattern that resembles a cathedral.

In terms of stability, plain sawing leaves the wood more susceptible to cupping, crowning, and gapping than the other methods. However, plain sawn is the least expensive of the options, in large part because it wastes the least wood.

For many, the affordability of plain sawn is just icing on the cake—they love the distinct, bold grain patterns this method produces.

Quarter sawn

This milling method begins by sawing a log into four quarters, and then cutting each quarter perpendicular to the growth rings of the log.

Quarter sawing produces a relatively straight, even grain that provides more stability than plain sawn planks have, with less tendency to expand and contract with moisture and temperature variations.

In some species of wood, the quarter sawn method also produces subtle, ribbony “ray fleck” patterns across the straight grain. Quarter sawn oak flooring, in particular, has beautiful ray flecks.

Customers pick this cut when they want to highlight the ray fleck but minimize the large grain of plain sawn.

Rift sawn

With the rift sawn method, logs are also quartered. However, rather than being cut perpendicular to the growth rings, each quarter-log is cut along the radius of the original log.

This method results in the most stable boards of the four methods and produces an undeniably elegant and refined look, with a linear grain pattern with no flecking.

However, it’s also the most expensive option (and the least common) because it results in a lot of wasted triangles of wood between each plank—frequently almost as much waste as usable wood.

Rift and quartered

Because of the expense of pure rift sawn or pure quarter sawn flooring, it has become common to use a combination of quarter sawn and rift sawn methods. “Rift and quartered” is in fact the most popular option these days for customized flooring.

To make rift and quartered planks, the log is still quartered, but the quarter-log is cut along alternating sides, producing a combination of rift sawn and quarter sawn characteristics in the planks.

Homeowners choose this method because it minimizes the grain, has good stability, and is the least expensive specialty cut.

Selecting among the milling options is essentially a matter of personal taste. We suggest you visit our showroom and look at samples of each method. You’ll also be able to talk to one of our hardwood flooring specialists about how the milling method affects specific types of hardwood.